Effective collaboration with a towel wholesaler determines the success of many hospitality and retail operations. Buyers often face issues such as unstable GSM, inconsistent colorfastness, and late shipments. These challenges can lead to customer dissatisfaction and lost revenue.

Common sourcing mistakes include:

Overlooking GSM and fabric details, which impacts towel quality.

Ignoring customization options, missing brand opportunities.

Underestimating logistics experience, causing delivery delays.

This article offers buying tips to help professionals avoid costly mistakes, evaluate towel quality, and select reliable partners. Readers will find clear strategies to maximize value and streamline their sourcing process.

Key Points

Understand GSM and fabric types. Higher GSM means better quality towels that are thicker and more absorbent.

Ensure material traceability. Reliable suppliers provide documentation to track quality and consistency.

Choose certified suppliers. Certifications like OEKO-TEX and GOTS guarantee ethical and high-quality products.

Evaluate supplier reliability. Check references and on-time delivery records to avoid disruptions.

Explore customization options. Embroidery and branding enhance your towels’ visibility and appeal.

Clarify pricing structures. Understand how fabric type, GSM, and size affect costs to negotiate better deals.

Request regular updates. Maintain clear communication with suppliers to stay informed about order status.

Build long-term partnerships. Investing in relationships with suppliers leads to consistent quality and support.

Towel Wholesaler Quality Standards

Fabric Types & GSM

Buyers often overlook the importance of fabric type and GSM when sourcing towels. GSM, or grams per square meter, directly affects towel thickness, absorbency, and durability. Low GSM towels feel thin and wear out quickly. High GSM towels, such as those used for bath towels, provide superior softness and absorbency, making them ideal for hospitality. Cotton remains the preferred material for most wholesale towels due to its natural feel and performance. Some suppliers offer blends with bamboo or modal for added softness or sustainability. Always request detailed specifications for GSM and fabric composition before confirming an order.

Tip: Compare GSM values for bath and hand towels to ensure consistency across your product range.

Material Sourcing & Traceability

Material traceability ensures consistent quality in every towel shipment. Reliable suppliers maintain digital records of yarn batches, twist counts, and moisture levels. This level of detail allows buyers to trace any quality issue back to its source. Hede Textile, for example, uses a digital database to track every batch, minimizing color deviation and ensuring uniformity in wholesale towels. Buyers should ask for documentation on yarn sourcing and request sample reports. Consistent material sourcing reduces the risk of unexpected defects and supports long-term business relationships.

Key Traceability Checks | Why It Matters |

|---|---|

Yarn batch records | Ensures color and texture match |

Supplier certifications | Confirms ethical sourcing |

Moisture/twist data | Prevents shrinkage and defects |

International Quality Benchmarks

International certifications set the standard for towel quality and safety. Certifications such as OEKO-TEX and GOTS indicate that towels meet strict environmental and social criteria. These benchmarks assure buyers that products are free from harmful substances and produced under ethical conditions. Working with certified suppliers demonstrates a commitment to quality, sustainability, and social responsibility. Businesses that choose certified wholesale towels gain confidence in their purchases and appeal to eco-conscious consumers.

Certifications like OEKO-TEX and GOTS guarantee high-quality towels.

Certified suppliers follow ethical and sustainable practices.

Eco-friendly towels attract a broader customer base.

Note: Always verify certification documents and request third-party test reports for each shipment.

A towel wholesaler that invests in multi-stage quality control and international standards, such as Hede Textile, provides buyers with peace of mind. Consistent quality, traceable materials, and recognized certifications form the foundation of successful wholesale partnerships.

Assessing Bulk Towel Supplier Reliability

Selecting a reliable bulk towel supplier is essential for any business sourcing towels in large quantities. Inconsistent deliveries, poor communication, or inadequate production capacity can disrupt operations and damage a brand’s reputation. Buyers must evaluate several factors to ensure their chosen supplier can meet expectations for quality, consistency, and service.

Supplier Background & References

A supplier’s track record provides valuable insight into their reliability. Experienced suppliers often have a history of successful partnerships and repeat clients. Buyers should request references or case studies from previous customers. Direct feedback reveals how the supplier handles orders, resolves issues, and maintains product quality.

Customer reviews highlight the actual performance of a bulk towel supplier.

Positive testimonials indicate strong customer service and reliability.

Negative feedback can uncover potential risks.

Requesting references or case studies helps buyers understand real-world outcomes.

Tip: Always verify references and look for suppliers with a proven history of delivering quality towels on time.

On-Time Delivery Records

Timely delivery is critical in the wholesale towels industry. Delays can lead to stock shortages and lost revenue, especially for hospitality businesses that rely on a steady supply of bath towels and hand towels. Leading towel wholesalers maintain an average on-time delivery rate above 95%. Some achieve perfect records, reflecting robust logistics and efficient workflow.

Consistent on-time delivery demonstrates a supplier’s commitment to meeting deadlines.

Reliable logistics reduce the risk of operational disruptions.

Buyers should request delivery statistics and clarify lead times before placing orders.

Description | |

|---|---|

Timely Deliveries | Regular on-time deliveries reflect good logistics. |

Quick & Honest Communication | Fast and clear responses indicate reliability. |

Positive Client Reviews | Genuine testimonials and repeat clients indicate trustworthiness. |

Production Capacity & Workflow

A bulk towel supplier must have the production capacity to handle both current and future order volumes. High-capacity weaving, dyeing, and finishing facilities ensure that large-scale orders for towels can be fulfilled without compromising quality. Suppliers with advanced production lines and structured workflows can maintain consistency across every batch of bath and hand towels.

Bchtowel, for example, operates advanced production lines designed for high-volume orders. Their workflow includes strict quality control at each stage, which is essential for meeting the demands of hospitality and retail clients. Buyers should assess a supplier’s daily output, equipment, and ability to scale production as needed.

Note: Evaluate whether the supplier’s production process includes multi-stage quality checks and clear documentation for each order.

A reliable towel wholesaler combines strong production capacity, transparent communication, and a history of on-time deliveries. By verifying references, reviewing delivery records, and understanding the supplier’s workflow, buyers can minimize risk and build long-term partnerships in the wholesale towels market.

-15-1-1024x538.jpg)

Wholesale Towels Customization Options

Embroidery & Branding

Embroidery and branding play a vital role in the wholesale market for towels. Many buyers seek ways to distinguish their bath and hand towels with unique logos or text. Most towel wholesalers provide flexible customization options, allowing businesses to enhance their brand visibility. Embroidery delivers a premium, long-lasting finish, while branding techniques such as high-density stitching and reactive digital printing offer additional ways to integrate logos.

Customization Options | Description |

|---|---|

Embroidery | Stitched logos or text for a premium, long-lasting finish |

Branding | Logo integration using embroidery or advanced printing methods |

Leading suppliers, including ACME Textile, offer customization on products to match business needs. They use quality fabric and premium embroidery thread to ensure durability and a professional appearance. Buyers should confirm the available customization options and review sample work before finalizing an order.

Tip: Request embroidery samples to evaluate thread quality and stitching precision before bulk production.

Jacquard & Printing Choices

Jacquard and printing choices expand the range of flexible customization options for wholesale towels. Jacquard weaving allows for intricate patterns and logos to become part of the towel’s structure, creating a high-end look. Printing methods, such as reactive or transfer printing, enable vibrant designs and color gradients.

The selection of jacquard or printing impacts both cost and lead time. Jacquard woven towels have distinct pricing structures that depend on order quantity. Pre-production samples and proofs add to the overall cost. Lead times may extend due to the need for sample approval and the complexity of the design. For large embroidery or ColorFusion orders, pre-production samples are mandatory, which can further influence both cost and delivery schedules.

Buyers should plan for these factors when requesting advanced customization. Clear communication with the towel wholesaler ensures that expectations for design, timing, and budget align.

Packaging & Labeling Flexibility

Packaging and labeling serve as the final touch in the customization process for towels. Wholesale suppliers recognize the importance of presentation, especially for retail and hospitality clients. Flexible customization options include branded bags, eco-friendly packaging, custom boxes, and personalized labels.

A towel wholesaler can provide packaging solutions that match the client’s market requirements. Options range from simple plastic bags to premium gift boxes. Custom labeling supports brand recognition and helps with inventory management. Buyers should specify packaging preferences early in the order process to avoid delays.

Note: Well-designed packaging and clear labeling enhance the perceived value of wholesale towels and support a consistent brand image.

Pricing & Payment Terms with Towel Wholesalers

Price Structure Breakdown

Understanding how towel wholesalers set their pricing helps buyers make informed decisions. Pricing for towels in bulk depends on several key factors. The type of fabric plays a major role. Cotton towels, especially those made from long-staple fibers, often command higher prices due to their softness and durability. GSM, or grams per square meter, directly affects the density and absorbency of each towel. Higher GSM means thicker, more absorbent towels, which usually cost more.

Other important elements include the size and intended use of the towels. Bath towels and hand towels have different price points because of their dimensions and material requirements. Durability and absorbency also influence pricing, as commercial buyers need towels that withstand frequent washing. Supplier reputation and the balance between cost and quality matter as well. Buyers should always compare the cost of towels against their expected lifespan and performance.

Key components that influence pricing for wholesale towels include:

Type of fabric (cotton, blends, or specialty fibers)

GSM (density and absorbency)

Size and application (bath, hand, or specialty towels)

Durability and maintenance requirements

Supplier reputation and service level

Sustainability features

A clear understanding of these factors allows buyers to negotiate better deals and avoid unexpected costs. Transparent pricing structures also help businesses plan budgets and forecast expenses for large-scale towel purchases.

Payment Schedules & Discounts

Payment terms can significantly impact the overall value of a wholesale towel order. Many suppliers offer flexible payment schedules to accommodate different business needs. Some provide “Buy Now Pay Later” options through financing services, which help buyers manage cash flow. Others allow staged payments, such as a deposit before production and the balance before shipment.

Bulk orders often qualify for discounts, making large purchases more cost-effective. Suppliers may offer tiered pricing, where the unit price drops as order quantity increases. This approach benefits buyers who need a steady supply of bath towels and hand towels for hospitality or retail operations.

The table below summarizes common payment options and bulk buying benefits:

Supplier | Benefits of Bulk Buying | Payment Options |

|---|---|---|

Eliya Linen | Discounted prices for large quantities | Flexible terms available |

Fresh Towel | Exclusive bulk pricing for businesses | Staged payments supported |

TowelHub | Cost-effective pricing with discounts |

Buyers should always clarify payment schedules and available discounts before finalizing an order. Clear agreements on payment terms reduce misunderstandings and support long-term supplier relationships. Negotiating favorable terms can improve cash flow and maximize the value of every towel purchase.

Tip: Request written confirmation of all payment terms and discount structures to ensure transparency and avoid disputes.

Towel Dimensions & Application Fit

Standard Sizes for Hospitality & Retail

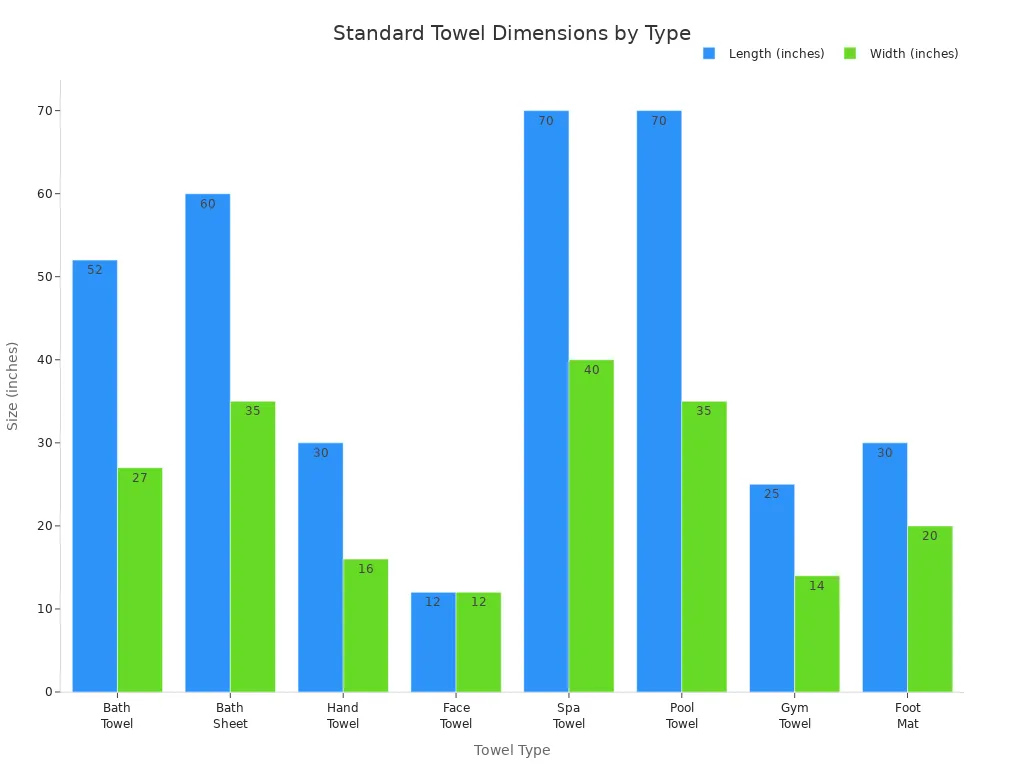

Selecting the right towel dimensions ensures a seamless fit for each application in hospitality and retail environments. Standardized sizing helps buyers maintain consistency across properties and simplifies inventory management. Most towel wholesalers offer a range of sizes tailored to specific uses, from guest bathrooms to spas and gyms. The following table summarizes the most common towel dimensions and their best applications:

Towel Type | Standard Size (in inches) | Best Usage |

|---|---|---|

Bath Towel | 27 x 52 / 30 x 56 | Guest bathrooms, general drying after a shower or bath |

Bath Sheet | 35 x 60 / 40 x 70 | Premium comfort, luxury suites |

Hand Towel | 16 x 30 / 18 x 32 | Near sinks, guest rooms, spas |

Face Towel / Washcloth | 12 x 12 / 13 x 13 | Face washing, makeup removal, skincare |

Spa Towel | 40 x 70 / 35 x 72 | Spa and wellness centers, massages, relaxation |

Pool / Beach Towel | 35 x 70 / 40 x 72 | Pools, beaches, resort areas |

Gym / Fitness Towel | 14 x 25 / 16 x 27 | Gyms, fitness centers, sweat absorption |

Foot / Bath Mat | 20 x 30 / 22 x 34 | Outside showers, bathtubs, guest safety |

Buyers should match towel types and sizes to their intended use. Bath towels and bath sheets provide comfort for guests, while hand towels and face towels serve daily hygiene needs. Spa towels and pool towels offer specialized dimensions for wellness and leisure settings. Standard sizing streamlines ordering and supports brand consistency across multiple locations.

Custom Sizing for Special Needs

Some businesses require towels with non-standard dimensions to meet unique branding or operational requirements. Custom sizing allows buyers to tailor towels for specific applications, such as oversized spa wraps, compact gym towels, or branded promotional items. Towel wholesalers with strong production capacity can accommodate these requests efficiently.

Key considerations for custom sizing include:

Flexible order minimums may apply, depending on the level of customization.

Minimum order quantities for private label towels often start at 3000 pieces.

Production timelines can adjust to meet urgent needs if buyers communicate deadlines early.

Orders can be completed in as little as 5-7 business days once proofs receive approval.

Some towel styles support rush production options for faster delivery.

A towel wholesaler with strong production capacity manages both standard and custom orders without sacrificing quality or lead time. Buyers benefit from clear communication regarding minimums, timelines, and available options. Custom sizing ensures towels fit the exact needs of each property, event, or brand initiative, maximizing value in every wholesale order.

Color Consistency & Dyeing Quality

Colorfastness Testing

Color consistency remains a top priority for buyers of towels in the wholesale market. A single shipment with uneven shades or fading can disrupt brand image and customer satisfaction. Leading suppliers use a range of colorfastness tests to ensure each towel maintains its intended hue and resists fading during use.

The following table outlines the main testing methods used to evaluate colorfastness in towels:

Testing Method | Description |

|---|---|

Light Fastness | Measures resistance to sunlight or UV exposure by simulating outdoor conditions. |

Wash Fastness | Assesses resistance to laundering by evaluating color change and staining after agitation in detergent. |

Rub Fastness | Evaluates dye transfer from the fabric surface to another through rubbing under dry/wet conditions. |

Perspiration Fastness | Tests resistance to human sweat by treating samples with artificial perspiration and assessing color change. |

Bleach Fastness | Determines how well the color withstands household bleach by exposing samples to oxidizing agents. |

Dry Cleaning Fastness | Evaluates color retention after dry cleaning in solvents with mechanical agitation. |

A professional towel supplier follows a structured process for colorfastness testing:

Select the appropriate test based on the towel’s intended use.

Prepare test samples, often pre-washed to simulate real-world conditions.

Follow established protocols for each method.

Evaluate results for any signs of fading, bleeding, or color change.

Document findings to ensure compliance with international standards.

Buyers should request test reports for every batch of wholesale towels. These reports provide objective proof that the towels will withstand repeated washing, exposure to sunlight, and contact with sweat or cleaning agents. Consistent colorfastness protects a brand’s reputation and reduces the risk of costly returns.

Batch-to-Batch Consistency

Maintaining color consistency across multiple batches presents a significant challenge in large-scale towel production. Even minor variations in dye lots can result in noticeable differences, especially for hospitality or retail chains that require uniformity.

-7-1024x538.jpg)

Towel manufacturers implement several controls to achieve batch-to-batch consistency:

Process | Description |

|---|---|

Quality Checks | Each batch undergoes multiple checks for fiber strength, absorbency, and color accuracy. |

Pre-washing and Sanitizing | Towels are pre-washed and sanitized before packing to stabilize color and texture. |

Compliance | Orders are shipped in compliance with international hospital textile standards. |

Color specialists often keep standard color cards or digital references for each client. Before bulk production, they conduct lab dips to match the approved shade. During production, technicians monitor dyeing parameters and record each batch’s details for traceability. If a buyer requests a repeat order, the supplier can reference previous dye lots to ensure a close match.

Buyers should communicate their expectations for color consistency at the start of the order process. Requesting pre-production samples and keeping approved color standards on file helps prevent misunderstandings. Reliable wholesale suppliers, such as Hede Textile, use digital tracking and strict quality control to minimize color deviation and deliver towels that meet brand requirements every time.

Tip: Always review color samples under different lighting conditions to confirm accuracy before approving bulk production.

Quality Control in Wholesale Towels

Multi-Stage Inspection Process

A robust quality control system forms the backbone of any successful wholesale operation. Buyers expect consistent product quality in every shipment of towels. Leading manufacturers implement a multi-stage inspection process to catch defects early and maintain high standards. Each stage targets specific risks that can affect the final towel.

The following table outlines the main steps in the inspection process for wholesale towels:

Stage | Description |

|---|---|

Loom Setup | Inspect the loom setup to ensure correct tension and alignment of warp and weft threads. |

Fabric Inspection | Check for weaving defects such as missing threads, uneven weave, or loose loops. |

On-Loom Checks | Perform periodic checks on the loom to catch any issues early. |

Loop Cutting and Shearing | Monitor processes to achieve the desired texture. |

Finished Towel Testing | Test for softness, absorbency, shrinkage, and colorfastness. |

Final Inspection | Conduct a final visual inspection of each towel for defects before packaging. |

This structured approach ensures that towels meet strict standards for softness, absorbency, and durability. Technicians monitor each step, from loom setup to final inspection, to deliver a consistent product quality. Any towel that fails to meet requirements is removed from the batch. This process reduces the risk of defects reaching the customer and supports long-term trust between buyers and suppliers.

Tip: Buyers should request documentation of each inspection stage to verify that the supplier follows a comprehensive quality protocol.

Third-Party Testing Support

Third-party testing adds another layer of assurance for wholesale buyers. Independent laboratories evaluate towels for key performance indicators such as absorbency, colorfastness, and fiber strength. These tests confirm that the towels comply with international standards and meet the expectations of demanding markets.

Many buyers require third-party test reports before accepting a shipment. Suppliers who support this process demonstrate transparency and a commitment to consistent product quality. Hede Textile, for example, welcomes third-party inspections and provides full documentation for every order. This practice helps buyers avoid disputes and ensures that every towel meets the agreed specifications.

Buyers should communicate their testing requirements early in the order process. Clear expectations and documented results protect both parties and reinforce the value of a reliable wholesale relationship.

Logistics & Export Support from Bulk Towel Suppliers

Packaging Solutions

Effective packaging protects towels during transit and enhances brand presentation. Bulk towel suppliers offer a range of packaging solutions tailored to the needs of hospitality, retail, and promotional buyers. Custom towel packaging fits the size and shape of each order, reducing movement and minimizing damage. Packaging sleeves shield towels from dust and dirt, while also providing space for printed logos that reinforce brand identity. Sturdy boxes, made from kraft or cardstock, ensure product safety during bulk shipping and support efficient stacking in warehouses.

Packaging Type | Benefits |

|---|---|

Custom Towel Packaging | Tailored to size, shape, and branding requirements, maximizing protection and presentation. |

Packaging Sleeves | Protects towels from dust and dirt while enhancing brand image with printed logos. |

Sturdy Boxes (Kraft/Cardstock) | Ensures product safety and meets branding needs, ideal for bulk shipping. |

Many buyers choose kraft sleeves and cardboard boxes for secure shipping of bath towels. Custom packaging options also help businesses stand out in the wholesale towels market and improve customer satisfaction upon delivery.

Tip: Buyers should confirm packaging preferences early to avoid delays and ensure the towels arrive in optimal condition.

Shipping & Documentation

Shipping wholesale towels internationally requires precise coordination and complete documentation. Bulk towel suppliers manage the export process by preparing all necessary paperwork and working closely with freight forwarders. The following documents are essential for smooth customs clearance and legal compliance:

Document Type | Description |

|---|---|

Commercial invoice | A detailed document providing a breakdown of the shipped goods, including description, quantity, and value. |

Packing list | An itemized document detailing the contents of a shipment, including quantity, weight, and packaging type. |

Certificate of origin | An official document certifying the origin of the goods being exported. |

Bill of exchange | A financial document serving as a written order from the exporter to the importer for payment. |

Insurance certificate | A document confirming that the shipped goods are covered by insurance during transit. |

Purchase order or letter of credit | A legal document outlining the terms and conditions of the purchase. |

Customs bond | A financial guarantee ensuring compliance with customs regulations. |

Customs entry documents | Paperwork submitted to customs authorities for clearance. |

Certificates from partner agencies | Documents required for compliance with additional regulations. |

Export license | An official authorization permitting the legal export of specific goods. |

Suppliers take responsibility for providing export licenses. If a supplier does not provide an export license, the freight forwarder arranges one, usually at an additional cost. Buyers should coordinate with the freight forwarder in advance for any extra approvals from regulatory bodies. This proactive approach prevents customs delays and ensures timely delivery of towels.

A reliable wholesale supplier communicates regularly about shipment status and provides digital copies of all documents. This transparency supports efficient import processes and reduces the risk of costly errors. Buyers who understand the logistics and documentation requirements can streamline their supply chain and maintain consistent inventory levels.

Communication & After-Sales Service

Regular Updates & Transparency

Effective communication forms the backbone of successful wholesale relationships. Buyers expect regular updates throughout the production and shipping process. Leading suppliers provide timely information about order status, production milestones, and shipment schedules. This approach helps buyers plan inventory and avoid unexpected shortages.

Clear and transparent pricing remains essential in every transaction. Suppliers who share detailed breakdowns of costs, including material, labor, and logistics, build trust with their clients. Buyers appreciate receiving itemized invoices and prompt notifications about any changes in pricing or delivery timelines. Dedicated account managers often serve as the main point of contact, ensuring that communication stays consistent and professional.

A reliable towel supplier uses digital tools to enhance communication. Production photos, video walkthroughs, and shipment tracking links offer buyers real-time visibility. These practices reduce misunderstandings and support long-term partnerships in the wholesale towels market.

Tip: Request regular production updates and clear and transparent pricing documentation to maintain control over your orders.

Handling Defects & Returns

Defect management plays a critical role in after-sales service for towels. Suppliers must address issues quickly to protect the buyer’s reputation and maintain operational efficiency. Common defects in wholesale towels include sewing errors, seaming problems, and fabric inconsistencies. Technicians identify defective pieces during multi-stage inspections and set them aside for alteration or replacement.

Standard procedures for handling defects and returns include:

Isolating defective towels for review and correction.

Documenting the type of defect, such as sewing or fabric issues.

Implementing remedies like machine maintenance and material cleaning to prevent recurrence.

Communicating findings with buyers and proposing solutions.

Suppliers often measure defect rates using metrics such as defect per hundred units and percent defectives. These indicators help buyers assess the overall quality of each shipment. When returns become necessary, suppliers coordinate logistics and provide clear instructions for packaging and shipping the affected towels.

A professional towel supplier supports buyers by offering prompt responses and practical solutions. This commitment to after-sales service strengthens trust and encourages repeat business in the wholesale sector.

Defect Type | Description | Remedy |

|---|---|---|

Sewing defect | Errors in machine operation | Regular maintenance |

Seaming defect | Issues from operator-machine interaction | Proper handling procedures |

Fabric defect | Problems in dyeing or processing | Material cleaning |

Defective pieces | Items set aside for alteration | Correction or replacement |

Note: Buyers should document all defects and communicate with suppliers immediately to ensure efficient resolution.

Building Long-Term Partnerships with Towel Wholesalers

Trust & Mutual Growth

A long-term partnership with a supplier creates stability for any business that relies on towels. Buyers who invest in ongoing relationships with their towel supplier gain more than just reliable deliveries. They receive consistent quality, transparent communication, and proactive support. A supplier who understands the buyer’s business can anticipate needs and offer tailored solutions. This approach reduces the risk of supply chain disruptions and helps both parties grow together.

The following table outlines the main benefits of building a strategic partnership with a towel supplier:

Benefit | Description |

|---|---|

Consistent Supply | Ensures a steady supply of towels, preventing shortages during busy periods. |

Cost Savings | Reduces overall cost per towel through wholesale pricing, allowing savings to be redirected. |

Uniform Appearance | Ensures towels match in size, color, and texture, enhancing the visual appeal of the business. |

Improved Customer Experience | High-quality towels elevate customer satisfaction and reduce complaints. |

Operational Efficiency | Durable towels lower replacement costs and streamline laundry processes, improving overall efficiency. |

Reduced Waste | Longer-lasting towels generate less textile waste, supporting eco-friendly practices. |

A partnership mindset encourages open feedback and continuous improvement. Both the buyer and the supplier benefit from shared goals and mutual trust. Hede Textile, for example, maintains long-term relationships by providing consistent quality and adapting to client needs over time. This approach supports mutual growth and strengthens the supply chain.

Note: Buyers should schedule regular reviews with their supplier to discuss performance, address challenges, and set new goals.

Flexibility for Small & Urgent Orders

Flexibility remains a key factor in choosing a towel supplier. Many businesses face sudden changes in demand or require small batches for special events. A supplier who can handle small or urgent orders demonstrates true partnership. This flexibility allows buyers to test new products, respond to market trends, or cover unexpected shortages without committing to large volumes.

Hede Textile stands out by supporting small-batch production and fast turnaround for repeat clients. Their workflow accommodates urgent requests while maintaining quality standards. Buyers benefit from reduced lead times and the ability to scale orders as their business grows.

Key advantages of working with a flexible supplier include:

Quick response to urgent towel orders.

Support for small-batch or sample production.

Consistent quality, even in limited runs.

Transparent communication about timelines and capacity.

A supplier who values partnership will adjust production schedules and offer practical solutions for both large and small orders. This adaptability builds trust and ensures the buyer’s business remains agile in a competitive market.

Tip: Buyers should clarify minimum order quantities and lead times for urgent or custom towel orders during initial negotiations.

Industry Trends in Wholesale Towels

Eco-Friendly Materials & Sustainability

Sustainability shapes the future of the towel industry. Buyers now demand towels made from organic cotton, bamboo fibers, or recycled yarns. These materials reduce environmental impact and appeal to eco-conscious consumers. Many manufacturers invest in low-impact dyes and water-saving processes. Packaging innovation also plays a role. Factories introduce biodegradable bags and recyclable boxes to minimize waste. Hede Textile, for example, partners with dyeing facilities that use advanced filtration systems and eco-friendly chemicals. Buyers should request documentation on material sourcing and environmental practices. This approach ensures compliance with international standards and supports responsible sourcing.

Note: Choosing sustainable towels helps businesses meet regulatory requirements and strengthens their brand image with environmentally aware customers.

Smart Manufacturing & Digital Management

Smart manufacturing transforms how suppliers produce and deliver towels. Automation systems now handle folding, cutting, and packaging with high precision. These upgrades improve efficiency and reduce costs. Digital management tools track each towel batch from yarn to shipment, ensuring traceability and quality control. The integration of advanced folding technology and standardized product development streamlines production. Technical services support application performance and simplify operational complexity for buyers.

Aspect | Description |

|---|---|

Advanced Folding Technology | Automation systems and performance monitoring enhance efficiency and lower costs. |

Standardized Product Development | Folding specifications ensure consistent quality and reduce installation expenses. |

Application Support | Technical services optimize folding performance and simplify operations. |

Supply Chain Integration | Comprehensive systems improve sourcing reliability and cost structures. |

Specialized Application | Automatic folding machines serve various commercial needs and generate revenue. |

Comprehensive Service Offerings | Integrated solutions simplify adoption for manufacturers and buyers. |

Digital management systems provide real-time updates on inventory and production status. Buyers benefit from transparent communication and faster response times. These innovations allow suppliers to handle both large and small orders with consistent quality. As a result, businesses can adapt quickly to market changes and maintain a reliable supply of wholesale towels.

Tip: Buyers should prioritize suppliers who invest in automation and digital management for greater reliability and cost control.

Current towel industry trends focus on eco-friendly materials, advanced dyeing, and packaging upgrades. Buyers who stay informed about these developments gain a competitive edge and ensure their towel sourcing aligns with market expectations.

A successful partnership with a towel wholesaler depends on several core principles. Buyers should focus on quality, reliability, and open communication. The most important lessons include prioritizing hotel quality towels, understanding material and GSM, and selecting the right size for each hotel application. Consistent color, proper branding, and durability also matter. Applying these strategies helps businesses achieve reliable results and build lasting supplier relationships. Hede Textile demonstrates these best practices, making it a dependable choice for global towel sourcing.