Many global brands and importers recognize the embroidered towel as a value-added product that elevates both presentation and function. A recent market survey shows that 21% of hotel towel imports feature custom embroidery, reflecting a strong demand for premium quality and unique finishes.

Percentage | Description |

|---|---|

21% | Hotels that pay more for custom-embroidered towels |

Buyers often select embroidered towels for several reasons:

Enhanced aesthetic appeal through intricate design

Personalization for homes or businesses

Superior durability and color retention

Luxurious feel for guests

Versatility as gifts, decor, or branding tools

This ultimate guide addresses essential questions: What distinguishes an embroidered towel in the market? Which criteria define a high-quality towel for embroidery? How can importers ensure both durability and strong market appeal?

Key Points

Embroidered towels enhance aesthetics and offer personalization, making them ideal for homes and businesses.

Choose high-quality materials like 100% cotton or bamboo blends for durability and absorbency in embroidered towels.

Consider the towel’s GSM (grams per square meter) to determine its absorbency and intended use, with higher GSM providing a plush feel.

Select the right embroidery technique, such as machine or hand embroidery, based on desired quality and production scale.

Utilize colorfast dyes to ensure vibrant colors that withstand washing and sunlight exposure.

Implement proper care practices, like gentle washing and avoiding bleach, to maintain the quality of embroidered towels.

Evaluate suppliers based on quality control, production capacity, and responsiveness to ensure reliable sourcing.

Explore seasonal designs and personalization options to enhance market appeal and customer satisfaction.

Embroidered Towel Basics

What Is an Embroidered Towel

An embroidered towel features decorative stitching applied to the fabric surface, often using advanced embroidery machines or skilled handwork. This process adds intricate patterns, logos, or monograms, transforming a standard towel into a personalized or branded item. Importers, retailers, and end users value embroidered towels for their ability to combine function with visual appeal. The embroidery process requires careful selection of base materials, such as 100% cotton or bamboo blends, to ensure the towel remains soft, absorbent, and durable.

Hede Textile has refined this craft over 30 years, leveraging high-speed looms and precise embroidery equipment. Their expertise ensures that each towel meets strict standards for size, color, and finish, supporting consistent export quality.

Key Features and Benefits

Embroidered towels stand out in the market for several reasons. The following table summarizes the main characteristics that attract importers and retailers:

Characteristic | Appeal to Importers and Retailers |

|---|---|

Aesthetic Appeal | Enhances bathroom decor and reflects individual style. |

Personalization | Offers unique designs tailored to consumer preferences. |

Luxurious Feel | Associated with high-end hotels and spas, adding a premium touch. |

Thoughtful Gifts | Serves as unique and high-quality gifts, appealing to consumers. |

End users benefit from embroidered towels in multiple ways:

Custom embroidery provides a professional look and greater design creativity.

These towels enhance the appearance of bathrooms or spas.

Personalization options, such as names or special dates, make them ideal gifts.

The use of luxury materials like Egyptian cotton or Turkish terry cloth elevates their appearance.

Embroidery is more durable than other decorative methods, ensuring designs last longer.

Businesses use embroidered towels to reinforce brand recognition and improve client experience.

Choosing premium materials, such as 100% cotton, enhances towel longevity. The quality of the embroidery also affects durability, as well-constructed designs resist fraying and maintain their appearance after repeated washing.

Market Trends

The market for personalized towels continues to expand. Projections indicate growth from $11.3 billion in 2024 to $21.65 billion by 2032. This trend reflects a shift in consumer preference toward unique and personalized products, which non-embroidered towels rarely offer. E-commerce platforms have made these products more accessible, further increasing their market share.

Jacquard weaving and advanced dyeing techniques also influence towel quality and market value. Hede Textile’s investment in weaving precision and stable dyeing partnerships ensures that embroidered towels maintain vibrant colors and consistent performance across large export orders. Their multi-stage inspection system and digital traceability provide measurable value for buyers seeking reliability and documentation.

Note: Buyers should evaluate towel GSM (grams per square meter), weaving type, and embroidery quality when sourcing embroidered towels. These factors directly impact absorbency, softness, and long-term performance.

Towel Selection for Embroidery

Material Choices: Cotton, Bamboo, Blends

Selecting the right material forms the foundation of a high-quality embroidered towel. Hede Textile prioritizes premium yarns, focusing on 100% cotton, bamboo blends, and specialty fibers. Each material offers distinct advantages for embroidery, durability, and user experience.

Material | Absorbency | Durability | Embroidery Suitability |

|---|---|---|---|

Turkish Cotton | High | High | Excellent (soft, durable, vibrant) |

Bamboo Blends | Very High | Moderate | Good (eco-friendly, smooth, delicate) |

Supima Cotton | High | Very High | Excellent (luxurious, long-lasting) |

Turkish and Supima cotton provide a soft, absorbent base that holds embroidery threads securely. Bamboo blends add eco-friendly appeal and a silky touch, though they require careful handling to maintain embroidery clarity. Hede Textile sources yarns from trusted regions and tests each batch for moisture and tensile strength, ensuring consistent performance and longevity.

-05-1024x538.jpg)

Weaving Types: Terry, Velour, Jacquard

The weaving method directly impacts the appearance and durability of embroidery. Hede Textile offers terry, velour, and jacquard weaves, each suited to different market needs.

Terry weave, with its plush loops, delivers high absorbency and a soft hand feel. However, the loops can obscure fine embroidery details. To address this, Hede’s technicians recommend dense fills or bold satin stitches for clear, visible designs. They also use cross-stitched underlays and multiple runs to stabilize the embroidery and prevent stitches from sinking into the pile.

Velour towels feature a sheared surface, creating a smooth and luxurious canvas for intricate embroidery. This weave highlights detailed logos and patterns, making it a preferred choice for hotel and spa collections.

Jacquard weaving integrates patterns directly into the fabric, offering a premium look and feel. This method supports both woven designs and embroidered accents, providing flexibility for custom branding.

Tip: Embroidery appears best on strong, stable fabrics. Flimsy materials require more underlay stitches, which can affect both appearance and durability.

GSM and Absorbency

GSM (grams per square meter) measures towel density and weight. This metric influences absorbency, softness, and the overall feel of the finished product. Hede Textile maintains strict GSM tolerances, ensuring each towel meets the intended specification for its market segment.

Lightweight towels (300-400 GSM) suit sports or kitchen use, offering quick drying and easy storage.

Medium-weight towels (500-600 GSM) work well for everyday bathroom use, balancing absorbency and comfort.

Heavyweight towels (600-900 GSM) deliver a luxury experience, often chosen for spas and hotels.

Towels with higher GSM, typically 400 and above, provide superior absorbency and a plush, comfortable feel. This enhances the tactile quality of embroidered designs and supports long-term durability. Hede’s quality control team tests each batch for water absorption time and weight consistency, documenting results for full traceability.

Note: Buyers should consider the intended use, drying time, and storage needs when selecting GSM. Higher GSM means more absorbency and a softer touch, but also longer drying times and increased storage space.

Hede Textile’s expertise in material selection, weaving, and GSM management ensures every embroidered towel delivers both performance and luxury, meeting the expectations of global importers and end users.

Color Fastness and Dyeing

Color fastness stands as a critical factor in the production of every embroidered towel. Buyers expect vibrant, consistent colors that withstand repeated washing, exposure to sunlight, and daily use. Hede Textile addresses this demand by partnering with advanced dyeing facilities in Hebei, where each towel undergoes a rigorous dyeing process designed for maximum color retention.

The dyeing process begins with careful pretreatment. Mercerizing and scouring prepare the towel fibers, enhancing the surface and reducing friction. This step minimizes floating color and improves the bond between dye and fiber. Softeners are then applied to maintain the smoothness of the fabric, which helps dyes adhere more effectively and reduces the risk of color loss during embroidery or washing.

Hede Textile relies on reactive dyeing technology for most luxury towel lines. This method produces deep, uniform shades and ensures that colors remain stable even after frequent laundering. The use of fixing agents further locks in color, while thorough washing removes any unreacted dyes or floating pigments. These steps guarantee that each embroidered towel maintains its original appearance and resists fading over time.

The choice of dye type directly impacts both the colorfastness and the durability of embroidery. The following table compares common dye types used in towel manufacturing:

Dye Type | Colorfastness | Durability | Best Use Cases |

|---|---|---|---|

Synthetic Dyes | Superior color retention, withstands washing and UV exposure | Ideal for high-wear items like towels | Uniforms, towels, outdoor items |

Natural Dyes | Tends to fade quickly under UV light and frequent washing | Better for low-wear projects | Decorative items, eco-conscious brands |

Synthetic dyes offer the best performance for towels intended for daily use. They provide strong resistance to fading and maintain the clarity of embroidery, even on high-GSM or luxury products. Natural dyes, while appealing for eco-friendly collections, suit decorative or low-wear items due to their lower resistance to washing and sunlight.

Hede Textile’s color specialists conduct multiple lab dips for each order, ensuring that every towel matches the approved shade. Standard color cards are kept on file for repeat clients, supporting consistent reorders and brand identity. The factory’s digital traceability system records every dye lot, allowing buyers to track color performance and batch history with confidence.

Tip: Buyers should request documentation of color fastness testing, including wash and rub fastness grades. Hede Textile supports third-party testing to verify that every luxury towel meets international standards for color stability.

Color fastness and advanced dyeing techniques play a decisive role in the long-term value of an embroidered towel. By investing in stable dyeing partnerships, strict pretreatment, and comprehensive testing, Hede Textile ensures that each towel delivers vibrant color, lasting embroidery, and a premium user experience.

Embroidery Techniques & Tools

Hand vs. Machine Embroidery

The embroidered towel market recognizes two primary approaches: hand embroidery and machine embroidery. Each method offers distinct advantages for buyers and end users.

Hand embroidery delivers a unique, artisanal touch. Every stitch reflects the embroiderer’s skill, resulting in subtle variations that add character to each towel.

Machine embroidery produces consistent, uniform results. This method suits large-scale production, where precision and repeatability are essential.

Experienced professionals can distinguish between the two by examining stitch quality and thread interaction.

Personal preference often guides the choice, especially for decorative or limited-edition towels.

Hede Textile invests in advanced embroidery machines to meet the demands of global importers. The following table outlines the advantages of using these machines for towel production:

Advantage | Description |

|---|---|

Creates designs that withstand frequent washing, ideal for towels. | |

Customization | Offers endless options for personalizing towels with monograms or branding. |

Professional Finish | Provides a polished look, enhancing aesthetic appeal and perceived value. |

Time Efficiency | Enables quick, accurate replication of designs, improving production efficiency. |

Marketing Advantage | Embroidered products serve as promotional items, increasing brand visibility. |

Artistic Freedom | Allows creativity with different stitch types, colors, and textures in textile customization. |

Long-Term Investment | High-quality designs contribute to customer satisfaction and product longevity. |

Machine embroidery dish towel kits and embroidery dish towel kits have become popular among brands seeking both speed and quality. These kits enable buyers to achieve professional results with minimal training. Hede Textile’s production lines utilize these advanced techniques for professional results, ensuring every embroidered towel meets strict export standards.

Stabilizers and Hooping

Stabilizers play a critical role in achieving clean, durable embroidery on towels. The right stabilizer prevents stitches from sinking into the towel’s pile and maintains the clarity of the design.

Cutaway stabilizers provide long-lasting support, especially for dense designs or stretch fabrics.

Tear-away stabilizers are recommended for towels, offering a tidy finish and easy removal.

Water-soluble toppers sit on top of the fabric, holding down the nap and ensuring stitches remain visible. This is essential for terry cloth towels, where the pile can obscure fine details.

When a cleaner back is desired, water-soluble stabilizers are preferred. For denser embroidery, a tear-away or light cut-away stabilizer adds extra support. Hede Textile’s technicians select stabilizers based on design density and towel type, ensuring optimal results for every order.

Proper hooping technique also affects embroidery quality. Several methods exist:

The floating technique hoops only the stabilizer, placing the towel on top. This avoids crushing the pile and allows precise placement.

Magnetic hoops adapt to thick fabrics, preventing hoop burn and streamlining the process.

Traditional plastic hoops can cause hoop burn, which is undesirable for high-quality towel embroidery.

Machine embroidery dish towel kits and embroidery dish towel kits often include guidance on stabilizer selection and hooping, supporting buyers in mastering dish towel embroidery techniques. Hede Textile’s operators follow step-by-step embroidery techniques to ensure every towel meets the highest standards.

Tip: Pre-washing towels before embroidery removes sizing agents and ensures better thread adhesion. This step is part of Hede Textile’s standard workflow.

Thread Types and Color Selection

Thread selection directly impacts the durability and appearance of embroidered towels. Polyester threads are the preferred choice for high-quality towel embroidery. They offer superior strength and withstand frequent washing and mechanical stress, making them ideal for heavyweight fabrics.

Color selection influences both visual appeal and marketability. Brands use color to shape perception and evoke emotional responses. Proper thread color enhances the overall look of the towel and can drive consumer purchasing decisions.

The choice of thread colors affects brand recognition.

Well-chosen colors increase the attractiveness of embroidered towels.

Emotional responses to color can influence buying behavior.

Gradient threads, also known as variegated or ombré threads, introduce a range of color transitions. These threads add depth, texture, and mood to embroidery, making each towel visually engaging.

Machine embroidery dish towel kits and embroidery dish towel kits provide a wide palette of thread options, supporting creative branding and personalization. Hede Textile’s design team collaborates with clients to select thread types and colors that align with brand identity and market trends.

Note: Step-by-step video tutorial resources and written tutorial guides help buyers and operators master advanced techniques for professional results. Hede Textile offers both formats to support continuous improvement and consistent quality.

By focusing on the right embroidery tools and techniques, buyers can ensure every embroidered towel delivers lasting value, vibrant color, and a premium finish. Mastering dish towel embroidery techniques and following step-by-step embroidery techniques elevate both product quality and brand reputation.

Laydown Stitch and Knockdown Techniques

Laydown stitch and knockdown techniques play a vital role in achieving professional results on every towel, especially those with a high-pile surface like terry cloth. These methods address a common challenge in embroidery: the towel’s loops can interfere with the clarity and durability of the design. Hede Textile’s embroidery specialists use these techniques to ensure that every embroidered towel meets the highest standards for export and retail.

The laydown stitch, sometimes called a “nap-taming” or “base” stitch, involves placing a layer of stitches before the main design. This step compresses the towel fibers, creating a smooth foundation for the embroidery. The knockdown technique works similarly, using a low-density fill to flatten the pile in the embroidery area. Both methods help the main design stand out sharply, even on plush or textured towels.

Key benefits of laydown stitch and knockdown techniques include:

They compress the towel’s fibers, preventing loops from poking through the embroidery.

They enhance the clarity and definition of logos, monograms, or decorative patterns.

They improve the durability of the design, reducing the risk of thread snagging or distortion during washing.

They ensure a consistent, professional appearance across large production runs.

Machine embroidery operators at Hede Textile select the appropriate technique based on towel thickness, pile height, and design complexity. For example, a dense logo on a luxury bath towel may require both a knockdown stitch and a water-soluble topper for maximum clarity. In contrast, a simple motif on a kitchen towel might only need a light laydown stitch.

Embroidery dish towel kits often include instructions for these techniques, making them accessible to both professionals and hobbyists. These kits guide users through the process, from hooping the towel to selecting stabilizers and applying the correct stitch sequence. Machine embroidery dish towel kits also provide pre-programmed designs that incorporate laydown and knockdown steps, ensuring consistent results.

The following table summarizes the main differences and applications:

Technique | Purpose | Best Use Cases |

|---|---|---|

Laydown Stitch | Compresses fibers for a smooth base | High-pile towels, dense designs |

Knockdown Stitch | Flattens pile with low-density fill | Terry cloth, large motifs, logos |

Machine embroidery dish towel kits have become popular among importers and retailers who value efficiency and quality control. These kits streamline production, reduce training time, and ensure that every towel meets export standards. Hede Textile’s advanced embroidery machines support both laydown and knockdown techniques, allowing for rapid customization and consistent quality across bulk orders.

Tip: Always test the laydown or knockdown stitch on a sample towel before full production. This step helps verify thread tension, stitch density, and overall appearance, minimizing the risk of defects in the final batch.

By mastering laydown stitch and knockdown techniques, buyers and manufacturers can achieve crisp, durable embroidery on any towel type. These methods add measurable value, supporting long-term performance and enhancing the visual appeal of every embroidered towel.

Kitchen Towel Embroidery Tips

Material and Design Considerations

Kitchen towel embroidery remains a popular choice for both retail and promotional markets. Buyers often select cotton or cotton-rich blends for their absorbency and durability. Hede Textile sources premium yarns and tests each batch for strength and moisture content. This ensures every towel provides a stable base for embroidery. The company’s experience with custom kitchen towel embroidery orders allows for a wide range of design options, from classic monograms to seasonal motifs.

Design clarity depends on both fabric texture and thread selection. Smooth, tightly woven towels display intricate embroidery best. For high-pile terry towels, Hede’s technicians recommend using a knockdown stitch to flatten the surface before applying the main design. Colorfast threads and stable dyes help maintain vibrant patterns after repeated washing. Hede’s color specialists conduct lab dips and keep color cards on file for consistent reorders.

Tip: Choose a towel with a GSM between 300 and 400 for kitchen towel embroidery. This weight balances absorbency, quick drying, and embroidery stability.

Placement and Sizing

Proper placement and sizing play a critical role in kitchen towel embroidery. Hede Textile’s production team uses digital templates to ensure each design appears in the optimal location. Most buyers prefer embroidery near the towel’s lower edge, where it remains visible when folded or hung. For branding or promotional use, logos typically measure 3 to 4 inches wide, centered 2 inches above the hem.

The following table summarizes common placement guidelines:

Placement Area | Recommended Size | Application |

|---|---|---|

Lower Center | 3–4 inches wide | Logos, monograms |

Corner | 2–3 inches wide | Decorative motifs, initials |

Full Width Border | 1–2 inches high | Repeating patterns |

Hede’s embroidery machines maintain precise alignment, even on bulk orders. This accuracy supports consistent branding and professional presentation across every embroidered towel.

Care for Embroidered Kitchen Towels

Proper care extends the life of kitchen towel embroidery. Hede Textile advises buyers to recommend gentle washing cycles and mild detergents to end users. Avoiding bleach and high-heat drying preserves both the towel fibers and the embroidery threads. The company’s towels undergo wash and rub fastness testing to ensure designs remain vibrant and intact.

Wash towels in cold or warm water with similar colors.

Tumble dry on low or line dry to prevent shrinkage.

Iron on the reverse side if needed, avoiding direct heat on the embroidery.

Hede includes care labels and documentation with every export order. This supports retailers and importers in providing clear aftercare instructions, reducing returns and enhancing customer satisfaction.

Note: Buyers can request third-party testing reports for colorfastness and durability. Hede’s multi-stage inspection system ensures every kitchen towel embroidery order meets international standards.

Ultimate Guide to Embroidered Dish Towels

Design Inspiration

Buyers often seek creative design inspiration when selecting embroidered dish towels for retail or promotional use. Popular motifs include geometric patterns, botanical elements, and culinary icons such as utensils or fruits. These designs enhance the visual appeal of each towel and support brand differentiation. Hede Textile’s design team tracks international trends and collaborates with clients to develop unique kitchen towel embroidery concepts. They use digital modeling tools to visualize patterns before production. This approach ensures that every towel aligns with the target market’s preferences and maintains a consistent brand image.

Design inspiration and patterns play a critical role in product development. Hede’s workflow allows clients to submit sketches or reference images. The team then refines these ideas into production-ready files. This process supports rapid sampling and efficient bulk manufacturing. Buyers receive digital previews and physical samples for approval, reducing the risk of miscommunication and ensuring satisfaction with the final embroidered towel.

Seasonal and Gift Ideas

Seasonal kitchen towel embroidery themes drive strong sales in both retail and gifting markets. Spring motifs might feature florals or pastel colors, while autumn designs often include pumpkins or leaves. Winter collections highlight snowflakes, holiday icons, or festive messages. These embroidered dish towels serve as personalized gifts for holidays, housewarmings, or special occasions.

Hede Textile offers a flexible sample service that enables buyers to test new seasonal designs before committing to large orders. The factory can produce small batches for market testing or limited-edition runs. This capability supports quick adaptation to changing trends and maximizes sales opportunities. Each towel undergoes strict inspection for colorfastness and embroidery clarity, ensuring that every gift-quality product meets international standards.

Tip: Buyers can request custom packaging, such as gift boxes or eco-friendly bags, to enhance the presentation of embroidered dish towels for special occasions.

Branding and Personalization

Branding remains a key driver in the kitchen towel embroidery segment. Many importers choose to add company logos, slogans, or custom artwork to embroidered dish towels. This strategy increases brand visibility and creates a lasting impression with end users. Hede Textile’s advanced embroidery machines support detailed logo reproduction and color matching, even for complex designs.

Personalization options extend beyond logos. Buyers can request monograms, family names, or event dates, transforming each towel into a unique keepsake. The factory’s design-to-production workflow ensures that every personalized order receives careful attention, from digital proofing to final inspection. Hede’s sample service allows clients to review and approve embroidery placement, thread colors, and finishing details before bulk production.

Design inspiration and patterns tailored to specific markets help buyers stand out in a competitive landscape. Creative design inspiration, combined with reliable manufacturing and export expertise, positions Hede Textile as a trusted partner for embroidered dish towels in global markets.

Custom Towels & Personalization

Logo Embroidery

Logo embroidery transforms a custom towel into a powerful branding tool. Hede Textile uses advanced machine embroidery to reproduce company logos with precision and consistency. The embroidery team digitizes each logo, ensuring accurate color matching and sharp detail. This process supports both small and large-scale orders, making embroidered dish towels and other personalized towels suitable for hotels, spas, and promotional campaigns. Buyers receive digital proofs for approval before production begins. Hede’s embroidery machines maintain uniformity across every towel, supporting brand identity and professional presentation.

Tip: Request a pre-production sample to verify logo placement and thread color accuracy before bulk manufacturing.

Monograms and Custom Text

Monograms add a personal touch to custom towels, making them ideal for gifts, events, or luxury collections. Hede Textile offers a wide range of font styles and thread colors for monograms and custom text. The design team collaborates with clients to select the best layout, ensuring that each embroidered dish towel or bath towel reflects the intended style. Machine embroidery guarantees that monograms remain crisp and durable, even after repeated washing. Personalized towels with monograms and personalization options appeal to both retail and hospitality markets.

Monograms can feature single initials, couples’ initials, or full names.

Custom text may include dates, messages, or event details.

Hede’s embroidery process supports both classic and modern monogram styles.

The factory’s workflow for monograms and custom text includes digital mockups, sample approval, and strict inspection at every stage. This approach ensures that every personalized towel meets the highest standards for clarity and durability.

Packaging and Presentation

Packaging plays a crucial role in the appeal of custom towels. Hede Textile offers a variety of packaging solutions, including eco-friendly bags, gift boxes, and branded sleeves. Each embroidered dish towel or personalized towel can be presented in packaging that matches the client’s brand image or the occasion. The packaging team coordinates with embroidery and finishing departments to ensure that every towel arrives in perfect condition.

Buyers can choose from:

Biodegradable bags for sustainable collections

Custom-printed boxes for retail displays

Compression packaging for efficient shipping

The process from design to sample to bulk order follows a clear sequence:

Design consultation and digital proofing

Sample production and client approval

Bulk manufacturing with multi-stage inspection

Custom packaging and export documentation

Hede Textile’s integrated approach to custom towels, from logo embroidery to packaging, delivers consistent quality and strong market appeal. The company’s experience with embroidered towel production, machine embroidery, and export logistics ensures that every order meets international standards and buyer expectations.

Quality Control for Embroidered Towels

Inspection Steps

Hede Textile applies a multi-stage inspection system to ensure every embroidered towel meets international standards. The process begins with raw material checks and continues through each production phase. Inspectors use a structured approach to verify the quality of custom towels and embroidered dish towels.

Cotton fiber tests confirm purity and softness.

Fiber content analysis identifies the exact blend in each towel.

Cotton yarn tests measure evenness and tensile strength.

Weaving tests check density and stability.

Terry toweling fabric structure tests assess loop uniformity.

Dimensional stability tests ensure towels retain shape after washing.

Tensile strength tests evaluate resistance to tearing.

Durability tests simulate repeated washing cycles.

Absorbency tests measure moisture retention.

Dyeing tests verify color fastness and shade consistency.

Each step receives documentation in Hede’s digital traceability system. This approach supports transparency and rapid response if issues arise.

Common Defects and Solutions

Quality control teams monitor for common defects in custom towels and embroidered dish towels. These include uneven loops, color variation, loose threads, and misaligned embroidery. Inspectors isolate any defective towel for review and correction.

Uneven loops: Adjust loom tension and verify yarn quality.

Color variation: Cross-check dye lots and maintain strict batch control.

Loose threads: Refine embroidery machine settings and use proper thread types.

Misaligned embroidery: Calibrate machines and use digital templates for placement.

Hede’s process reduces defect rates and ensures professional finishing and washability. The company maintains a defect rate below 1.5%, supporting consistent export quality.

-15-1024x538.jpg)

Third-Party Testing

International buyers often request third-party testing for custom towels and embroidered dish towels. Hede Textile supports inspections by organizations such as SGS, BV, and Intertek. These tests confirm compliance with standards for absorbency, color fastness, and durability.

Country | Key Features | |

|---|---|---|

Pakistan | Premium cotton towels, softness, durability | OEKO-TEX Certified Production |

Vietnam | Low labor costs, improving product quality | Sustainable development strategies |

Turkey | Premium Turkish cotton towels, softness | Rich textile heritage, strategic location |

Egypt | High-quality Egyptian cotton, luxury | Known for exceptional absorbency and durability |

Hede aligns its inspection protocols with leading export markets. The company provides full documentation, including test reports and batch records, to support buyer confidence.

Tip: Buyers should confirm GSM tolerance, color fastness, shrinkage rates, and packaging consistency before placing orders for custom towels or embroidered dish towels. Requesting third-party test results adds another layer of assurance.

Embroidered Towel Care & Maintenance

Proper care and maintenance extend the life and appearance of every embroidered towel. Hede Textile recommends a set of best practices to help buyers and end users preserve embroidery quality, color vibrancy, and towel performance through repeated use.

Washing and Drying

Washing and drying methods have a direct impact on the durability of embroidery and the base towel fabric. Hede Textile advises the following steps for optimal results:

Hand washing remains the safest method for embroidered items. Use lukewarm water and a mild, phosphate-free detergent.

For machine washing, select a delicate cycle and place towels in a mesh laundry bag. This protects embroidery stitches from abrasion.

Wash one or two towels at a time to prevent tangling and ensure thorough cleaning.

Always use cold water to minimize color fading and avoid mixing with rough fabrics or items with zippers.

Avoid bleach and fabric softeners, as these can weaken embroidery threads and reduce color intensity.

After washing, lay the towel flat on a clean, dry surface. Reshape it to its original dimensions to prevent stretching or distortion of the embroidery.

Dry towels in a well-ventilated, shaded area. This prevents UV fading and maintains embroidery vibrancy.

Do not use a dryer, as high heat can shrink or damage both the embroidery and the towel fibers.

Flip the towel after a few hours to ensure even drying and prevent mildew.

Tip: Hede Textile includes detailed care labels with every export order, supporting consistent aftercare for all embroidered towel shipments.

Stain Removal

Effective stain removal forms a key part of towel care and maintenance. Address stains promptly to protect both the embroidery and the towel fabric.

Blot stains gently with a clean, damp cloth. Avoid rubbing, which can push stains deeper into the fibers.

Use a mild, color-safe stain remover. Test on a small, inconspicuous area first.

For stubborn stains, soak the towel in lukewarm water with a gentle detergent before washing.

Never use harsh chemicals or bleach, as these can damage embroidery threads and alter towel color.

Rinse thoroughly to remove all cleaning agents, then air dry as recommended.

Hede Textile’s export standards require all towels to pass wash and rub fastness tests, ensuring that embroidery and base fabrics withstand routine cleaning.

Storage Tips

Proper storage supports long-term towel care and maintenance. Hede Textile recommends the following guidelines:

Store towels in a cool, dry place away from direct sunlight to prevent fading and moisture buildup.

Fold towels neatly to avoid creasing or distorting embroidered areas.

Place towels on a flat shelf or in a breathable storage bag. Avoid overcrowding, which can crush embroidery and affect towel shape.

For long-term storage, insert acid-free tissue paper between folds to protect delicate embroidery.

Note: Hede Textile’s packaging team uses moisture-resistant and eco-friendly materials to maintain towel quality during shipping and storage.

By following these care and maintenance practices, buyers and end users can maximize the durability, appearance, and value of every embroidered towel. Hede Textile’s commitment to quality ensures that each towel meets international standards for performance and longevity.

Buyer Tips & Sourcing Advice

Supplier Evaluation

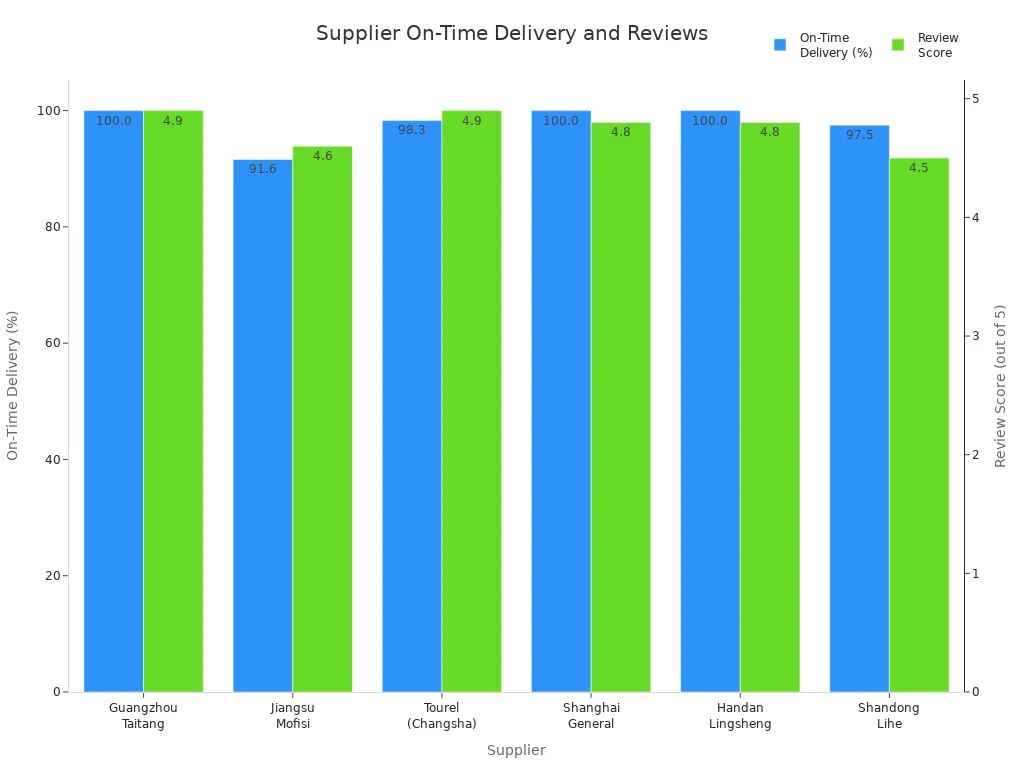

Selecting the right supplier is a critical step for any buyer seeking consistent quality in embroidered towel sourcing. Buyers should assess suppliers based on production capacity, on-time delivery, responsiveness, and documented quality control. A reliable supplier demonstrates transparent communication, provides clear documentation, and supports third-party inspections.

The following table compares several leading towel suppliers by location, delivery performance, response time, and review score:

Supplier | Location | On-Time Delivery | Response Time | Review Score |

|---|---|---|---|---|

Guangzhou Taitang Hotel Supplies Co., Ltd. | Guangdong | 100.0% | ≤3h | 4.9/5.0 |

Jiangsu Mofisi Weaving Co., Ltd. | Jiangsu | 91.6% | ≤2h | 4.6/5.0 |

Tourel (Changsha) Hotel Supplies Co., Ltd. | Hunan | 98.3% | ≤3h | 4.9/5.0 |

Shanghai General Textile Co., Ltd. | Shanghai | 100.0% | ≤2h | 4.8/5.0 |

Handan Lingsheng Hairdressing Products Co., Ltd. | Hebei | 100.0% | ≤2h | 4.8/5.0 |

Shandong Lihe Textile Co.,ltd. | Shandong | 97.5% | ≤3h | 4.5/5.0 |

ILEF | Sindh, PK | N/A | ≤1h | 5.0/5.0 |

Hede Textile stands out for its 24/7 production, multi-stage inspection, and export documentation support. The company’s digital traceability system and dedicated account managers ensure buyers receive timely updates and transparent communication throughout the order cycle.

Tip: Always request documentation of inspection results and production photos. This practice helps verify supplier reliability and product consistency.

Sampling and Small Orders

Sampling is essential for buyers who want to confirm quality before placing large orders. Leading suppliers offer flexible sample policies, allowing buyers to test towel materials, embroidery clarity, and colorfastness. Hede Textile provides standard, custom, and pre-production samples, with rapid turnaround and clear approval processes.

Small order flexibility benefits brands launching new collections or testing market response. Hede Textile accepts small batch orders, supporting buyers with limited initial demand. This approach reduces risk and builds trust between buyer and supplier.

Key points for sampling and small orders:

Request samples that match the final towel specifications, including embroidery and packaging.

Review sample reports for GSM, absorbency, and colorfastness.

Confirm sample fees and refund policies before proceeding.

Note: Sampling helps buyers evaluate both product quality and supplier responsiveness.

Packaging and Logistics

Packaging and logistics play a vital role in protecting towel quality and supporting brand presentation. Buyers should select suppliers who offer a range of packaging options, from moisture-resistant bags to eco-friendly boxes. Hede Textile coordinates packaging with embroidery and finishing, ensuring every towel arrives in perfect condition.

Efficient logistics management ensures on-time delivery and reduces the risk of damage during transit. Hede Textile’s proximity to major ports, combined with experienced export teams, supports smooth shipping and accurate documentation. The company provides full export support, including customs paperwork and real-time tracking.

Checklist for packaging and logistics:

Choose packaging that matches the towel’s market segment and branding needs.

Confirm carton integrity and labeling before shipment.

Request export documentation, including packing lists and certificates of origin.

Buyers who prioritize packaging and logistics gain a competitive edge in both retail and wholesale markets.

Sustainability and Compliance

Sustainability and compliance have become essential considerations for buyers sourcing embroidered towel products in today’s global market. Brands and importers must ensure that every towel meets both environmental and regulatory standards to access international markets and build consumer trust.

Leading certifications help buyers verify that each towel aligns with recognized benchmarks for safety, environmental responsibility, and ethical production. The following table summarizes the most important certifications for embroidered towel sourcing:

Certification Name | Focus Area |

|---|---|

Global Organic Textile Standard (GOTS) | Ensures at least 70% organic fibers and strict environmental and social criteria. |

OEKO-TEX® Standard 100 | Tests for harmful substances across all production stages, ensuring safety for human health. |

Fair Trade Certified™ | Promotes fair labor practices and safe working conditions for workers. |

Bluesign® | Evaluates the entire supply chain for resource efficiency and reduced environmental impact. |

Global Recycle Standard (GRS) | Focuses on recycled content and compliance with social and environmental criteria. |

Buyers benefit from these certifications in several ways:

They ensure product quality by maintaining consistent standards across textile products.

They help manufacturers comply with international and local regulations, reducing the risk of legal issues.

They build consumer trust by signaling that products meet high safety and sustainability standards.

They provide access to markets that require specific certifications for textile products.

Hede Textile integrates sustainability into every stage of towel production. The company partners with dyeing facilities that use water recycling and low-impact dyes. The factory implements energy-efficient weaving and finishing processes. All cotton waste is collected and repurposed, supporting waste reduction goals. Hede Textile also offers eco-friendly packaging options, such as biodegradable bags and recyclable boxes, to help buyers meet green market requirements.

Compliance documentation forms a core part of Hede Textile’s export service. The company provides buyers with detailed records, including test reports, batch traceability, and certificates of origin. Third-party testing by organizations such as SGS or Intertek is available upon request, ensuring that every towel shipment meets the highest standards for safety and sustainability.

Tip: Buyers should request certification copies and compliance documentation with each order. This practice supports smooth customs clearance and strengthens brand reputation in environmentally conscious markets.

Sourcing an embroidered towel from a supplier with strong sustainability and compliance practices ensures long-term value, market access, and consumer confidence.

Selecting the right embroidered towel supplier requires attention to material quality, advanced embroidery technique, and proven reliability. Buyers should evaluate each towel for consistent color, precise stitching, and customization options. Reliable communication and stable towel quality support long-term partnerships. Hede Textile stands out as a trusted partner with deep export experience and responsive service. For more information or custom towel requests, readers may contact Hede Textile’s export team.